Tabular Alumina

Key words:

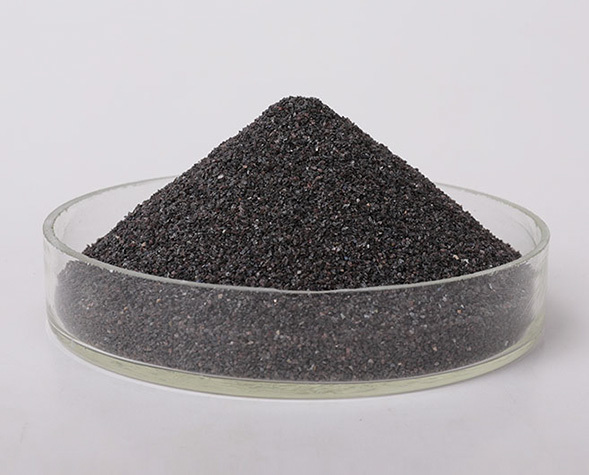

Tabular Alumina

Product Description

|

temperature. But the price is higher than other Alumina.Shape |

Chemical Composition |

Physical Composition |

||||||

|

Al2O3 |

Na2O |

SiO2 |

Fe2O3 |

Bulk Density |

Apparent porosity |

Water Absorption |

Size |

|

|

Granule |

≥99.1% |

≤0.40% |

≤0.10% |

≤0.05% |

≥3.5g/cm3 |

5% |

1.5% |

0.2-0.6mm |

|

0.5-1mm |

||||||||

|

0-1mm |

||||||||

|

1-3mm |

||||||||

|

3-6mm |

||||||||

|

5-10mm |

||||||||

|

Micro-powder |

≥99.1% |

≤0.40% |

≤0.15% |

≤0.10% |

≥3.5g/cm3 |

5% |

1.5% |

325mesh |

|

635mesh |

||||||||

Production process and characteristics:

Tabular Alumina (TA) is dense, pure sintered alumina that is completely shrunk after being burned at 1900℃ without any additives. TA is composed of large, well-developed hexagonal tablet shaped α-alumina crystal structure (up to 200 µ m). The content of Al2O3 is highly up to 99%. (Max.200 µ m), The porosity is roughly the same as fused alumina, with high purity, good volume stability and minimal shrinkage after reheating. The refractories or castables produced by TA have good thermal shock stability and bending strength after high temperature treatment. But the price is higher than other Alumina.

Application

Refractory use(steel, foundry, cement, glass, petrochemical, ceramic and waste incineration) and non refractory use (kiln furniture, filter for molten metal, filter for epoxy resins and polyester, insert catalyst supports and heat conductors).

Package:

1 MT big bag or 25kg paper bag *40 bags on one pallet ;As per customer’s requirement

Related Products