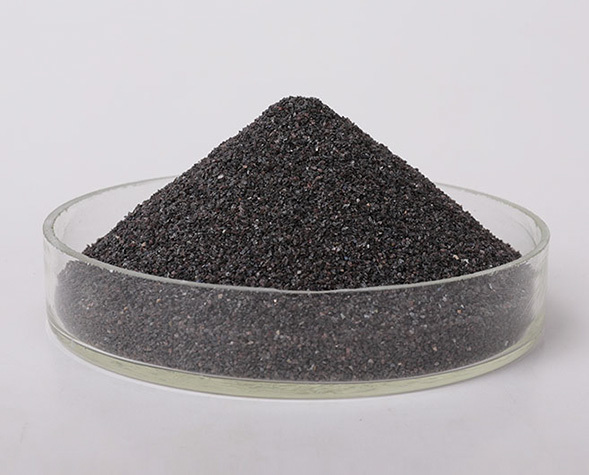

Bauxite

Color: Stone gray

Smelting furnace: Rotary kiln

Bulk: ≥2.45g/cm³

Water absorption rate: ≤6%

Smelting furnace: Rotary kiln

Bulk: ≥2.45g/cm³

Water absorption rate: ≤6%

Key words:

Bauxite

Product Description

Calcined bauxite is one of the main aluminum ores. Calcined bauxite contains aqueous alumina and aluminum hydroxide, which is formed under the lateriteization of tropical and subtropical aluminum rocks. Calcined bauxite is obtained by calcining (heating) high-quality bauxite at high temperature (85°C to 1600°C). This removes moisture and increases the alumina content. Compared with the alumina content of about 57% to 58% in raw bauxite, the alumina content of calcined bauxite is 84% to 88%, and the heating is carried out in a rotary kiln.

Calcined bauxite application

1. Aluminum metallurgy

2. Precision casting/investment casting

3. Refractory materials

4. Aluminum silicate refractory fibers: can be made into fiber felt, boards, and cloth.

5. Mix magnesium sand and bauxite slag with the binder and pour into the molten steel for better overall lining performance.

6. Production of bauxite cement

7. Abrasives

8. Ceramics industry

9. Chemical industry of various aluminum compounds.

2. Precision casting/investment casting

3. Refractory materials

4. Aluminum silicate refractory fibers: can be made into fiber felt, boards, and cloth.

5. Mix magnesium sand and bauxite slag with the binder and pour into the molten steel for better overall lining performance.

6. Production of bauxite cement

7. Abrasives

8. Ceramics industry

9. Chemical industry of various aluminum compounds.

Chemical Indicators

|

Chemical Ingredients |

||||||

|

grade |

Al₂o₃ |

Fe₂O₃ |

TiO₂ |

High+mgo |

Push (g/cm³) |

Water absorption rate % |

|

AL88 |

≥88 |

≤1.5 |

≤4.0 |

≤0.4 |

≥3.15 |

≤4 |

|

AL85 |

≥85 |

≤1.8 |

≤4.0 |

≤0.4 |

≥3.10 |

≤4 |

|

Al82 |

≥82 |

≤2.0 |

≤4.0 |

≤0.5 |

≥2.90 |

≤5 |

|

Al80 |

≥80 |

≤2.0 |

≤4.0 |

≤0.6 |

≥2.75 |

≤5 |

|

Al70 |

≥70 |

≤2.5 |

≤4.0 |

≤0.6 |

≥2.65 |

≤6 |

Related Products