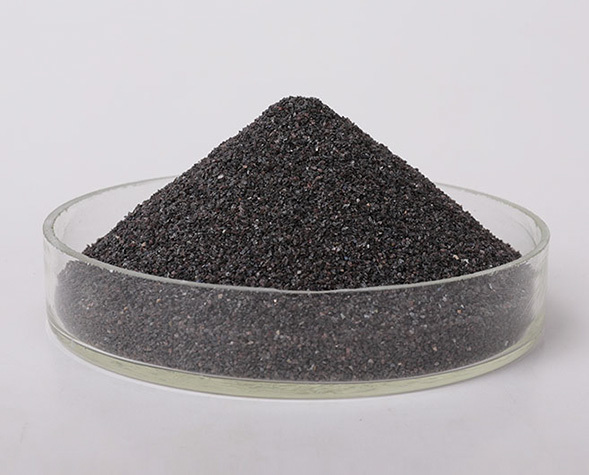

Brown Fused Alumina

Color: Brown

Crystal Shape: Trigonal

Mohs Hardness: ≥9.0

Melting Point(℃): 2050

True Density(g/cm³): ≥3.90

Key words:

Brown Fused Alumina

Product Description

Production process and characteristics

Using bauxite and charcoal (anthracite) as raw material, and fused under high temperature in electric arc furnace. The main chemical components are Al2O3, and TiO2. It also contains small amounts of SiO2 and Fe2O3, etc. The micro hardness is 1800-2200kg/mm2. The toughness is higher than Silicon Carbide. The abrasive tools made by brown fused alumina are suitable for grinding carbon steel, normal alloy steel, malleable cast iron and hard bronze etc. Brown fused alumina can also be used for making fine quality refractory etc. The refractoriness of high-alumina clinker is up to 1850℃.It has strong chemical stability and good physical properties.

Applications

Refractory Grade can use for:

1. unshaped refractory products: Iron Hook Castable, Ladle Castable, Light weight refractory castable, Gun-mix refractory;

2. shaped refractory products: Corundum bricks, Firebrick, Three major steel making and continuous casting pieces, Ultra-temperature.

Abrasive Grade can use for:

1. Abrasives: Lapping, polishing,decorative non-skid tile, and pressure blasting, Surface treatment, Grinding high carbon steel, high-speed steel and chilled steel, Precision casting.

2. Making abrasive tools: Ceramic bonded abrasives, Resin bonded abrasives, Coated abrasives.

1. unshaped refractory products: Iron Hook Castable, Ladle Castable, Light weight refractory castable, Gun-mix refractory;

2. shaped refractory products: Corundum bricks, Firebrick, Three major steel making and continuous casting pieces, Ultra-temperature.

Abrasive Grade can use for:

1. Abrasives: Lapping, polishing,decorative non-skid tile, and pressure blasting, Surface treatment, Grinding high carbon steel, high-speed steel and chilled steel, Precision casting.

2. Making abrasive tools: Ceramic bonded abrasives, Resin bonded abrasives, Coated abrasives.

Brown Fused Alumina (refractory)

Particle size | Al2O3 | SiO2 | TiO2 | Fe2O3 |

Micro-powder | ≥94.50% | ≤1.50% | ≤3.0% | ≤0.5% |

0-1mm | ≥95.00% | ≤1.20% | ≤3.0% | ≤0.5% |

1-3mm | ≥95.00% | ≤1.20% | ≤3.0% | ≤0.5% |

3-5mm | ≥95.00% | ≤1.20% | ≤3.0% | ≤0.5% |

5-8mm | ≥95.00% | ≤1.20% | ≤3.0% | ≤0.5% |

Brown Fused Alumina (abrasives)

Grit Size | Al2O3 | SiO2 | TiO2 | Fe2O3 |

12-80# | ≥95.00% | ≤1.00% | ≤3.0% | ≤0.5% |

100-180# | ≥95.00% | ≤1.20% | ≤3.5% | ≤0.5% |

220# | ≥94.50% | ≤1.50% | ≤3.5% | ≤0.5% |

Physical Performance Index

| Item | Index |

| Color | Brown |

| Crystal Shape | Trigonal |

| Mohs Hardness | ≥9.0 |

| Melting Point(℃) | 2050 |

| True Density(g/cm3) | ≥3.90 |

Packing

1 MT big bag or 25kg paper bag *40 bags on one pallet; As per customer’s requirement

Related Products