Blue Brown Fused Alumina VS Brown Fused Alumina

Blue Brown Fused Alumina with good cubic particle shape and high bulk density. It toughness, hydrophilicity, cleanliness, magnetic contents and hardness are better than bfa. Reduce expansion and black specks on vitrified abrasives. Improved durability makes them suitable for making top grade bonded abrasives in heavy-duty machining and double-disccylindrical grinding.

Augular shape: have good heat dissipation effect and improved durability, can used in making top-grade abrasive cloth, sandpaper, sanding belts, machining of low carbon steel, steel alloy, and special wood.

Availible size: F12-F220, P12-P220.

Particle size: Cubic, Angular.

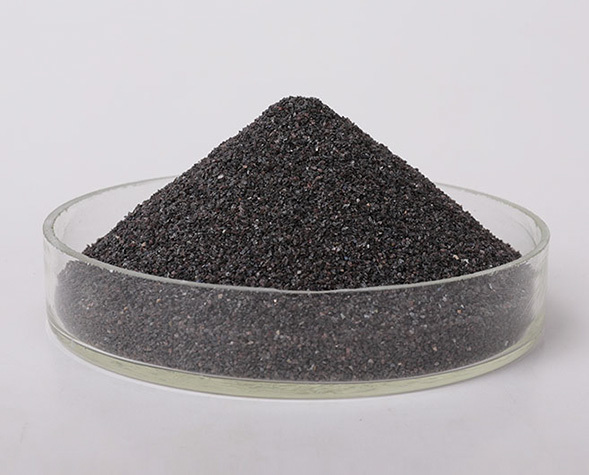

Brown Fused Alumina's micro hardness is 1800-2200kg/mm2. The toughness is higher than Silicon Carbide. The abrasive tools made by brown fused alumina are suitable for grinding carbon steel, normal alloy steel, malleable cast iron and hard bronze etc. Brown fused can also be used for making fine quality refractory etc. The refractoriness of high-alumina clinker is up to 1850℃.It has strong chemical stability and good physical properties.

Application: 1.Refractory, Casting etc 2.Bonded abrasives and Coated abrasives,ceramic grinding wheel, resin grinding wheel 3.Surface treatment/finishing 4.Lapping, polishing,decorative non-skid tile, and pressure blasting 5.Ceramic Tiles special ceramics 6.Fluidized Bed Furnaces and Skin / Dental Care 7.Grinding high carbon steel, high-speed steel and chilled steel.

Availible size: 0-1-3-5-8mm, 200mesh, 325mesh, F12-F220, P12-P220.

Particle size: Cubic, Angular.

alumina,steel,size,brown,fused,carbon,is,particle,the

Previous Page

Next Page

Previous Page

Next Page