Ruihang's Quality Control

Quality Control

To ensure the quality stability of each lot, we have a complete set of quality control procedures to rule every link of production

Strict quality control procedure

The main monitoring focus on 4 points: incoming inspection, in-process inspection, warehouse-in inspection and warehouse-out inspection, to ensure each lot out of our warehouse is qualified.

Large particles and pollutants control procedure

To further control large particles and pollutants, such as wood chips and plastic sheet, we specifically use stainless steel rotary vibrating screen after precision sieving.

Batch management system

1 ton, 1 batch, 1 testing result.

Cleanliness Control Procedure

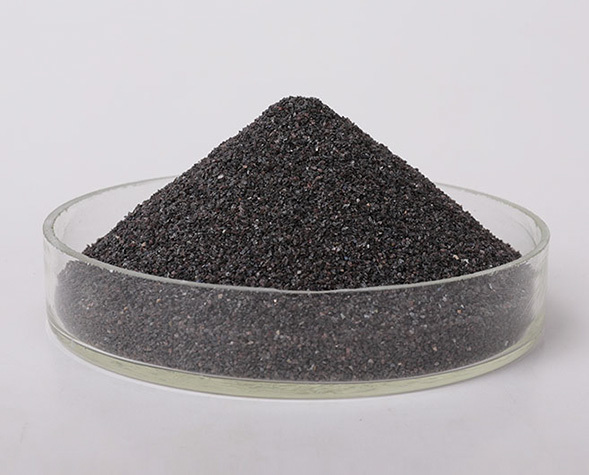

All abrasives are cleaned, air washing, water washing, acid and alkali washing, to ensure the cleanliness meets your requirements.

Magnetic Seperation Control Procedure

All abrasives are treated by magnetic separation, especially for the abrasive used for vitrified grinding wheel. We use 10000 Gs magnetic separator and make grinding wheel burning experiment to ensure that the grinding wheel is free from any rust spots.

Mixing System

The difference between the upper and lower limits will cause the quality fluctuation of the abrasive tools. We mix every batch to avoid this instability.

Sample Management System

To keep samples for at least two years, no matter samples before the order, or samples from the official order. The aim is to ensure the traceability of each batch.

Previous Page

Next Page

Previous Page

Next Page