Black Silicon Carbide Application

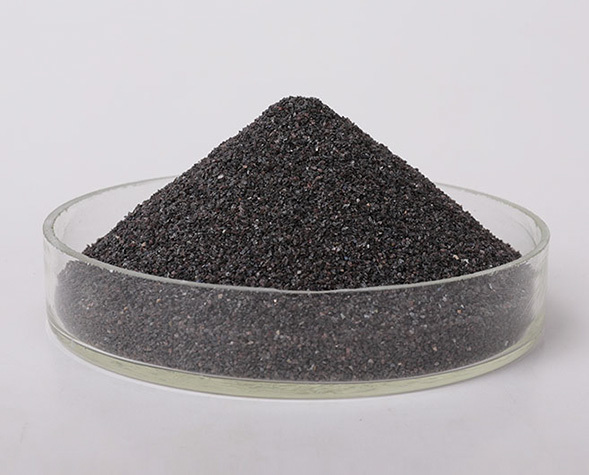

Black silicon carbide is brittle and sharp, and has high hardness, low expansion coefficient,good thermal conductivity and electrical conductivity. It takes petroleum coke and high quality silicon as raw materials, adds salt as additive, and is fused through the electric resistance furnace at high temperature. hexagonal crystalline of microscopic shape, 3300kg/mm³ of microhardness. Its hardness is higher than corundum but lower than diamond, cubic boron nitride and boron nitride among abrasives. Density is 3.2g/mm³, the natural bulk density of black silicon carbide abrasive is 1.2-1.6g /mm³, and the specific gravity is 3.20 - 3.25.

Black silicon carbide is brittle and sharp, and has high hardness, low expansion coefficient,good thermal conductivity and electrical conductivity. It takes petroleum coke and high quality silicon as raw materials, adds salt as additive, and is fused through the electric resistance furnace at high temperature. hexagonal crystalline of microscopic shape, 3300kg/mm³ of microhardness. Its hardness is higher than corundum but lower than diamond, cubic boron nitride and boron nitride among abrasives. Density is 3.2g/mm³, the natural bulk density of black silicon carbide abrasive is 1.2-1.6g /mm³, and the specific gravity is 3.20 - 3.25.

Black Silicon Carbide can used to make various bonded abrasives, for grinding and polishing stones, and for processing metal and non-metallic materials with low tensile strength, such as gray cast iron, brass, aluminum, stone, leather, rubber, etc.

Various coated abrasives, such as heavy abrasive belt, wet abrasive paper, vulcanized fiber disc, for grinding and polishing hard metals, copper, aluminum, glass, marble, granite, ceramics, plastics, wood, etc.

Sandblasting and refractories.

Black,Silicon,Caibide,Coated,Abrasive,steel,making,refractories,bonded,abrasives

Previous Page

Next Page

Previous Page

Next Page